Hello I am Claudio Cosentino, I am a production designer, a professor of Scenography at the Academy of Fine Arts of Catanzaro.

In an age where it is increasingly necessary to use digital modeling programs, and new open source tools are developed ever faster, the 3D modeling also invades other sectors in addition to those of the graphics, such as industrial, medical, building and space, through the use of 3D printers. Natural evolution of printing in two dimensions, 3D printing allows you to have a real reproduction of a digital model, created with a 3D modeling software.

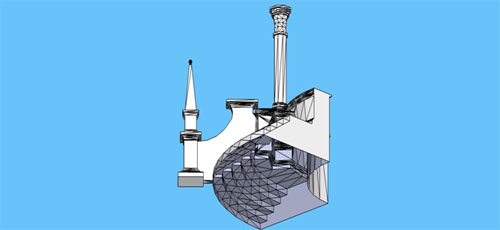

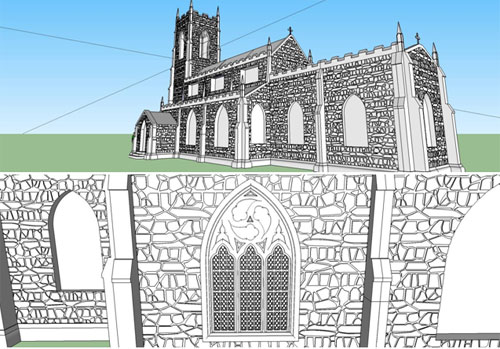

scenography created by art director Marco Trentini for the film "The Decameron" directorDavid Leland 2005

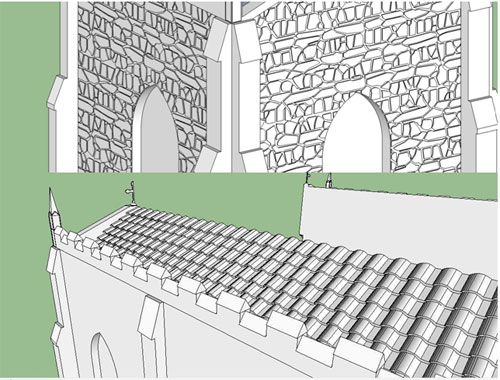

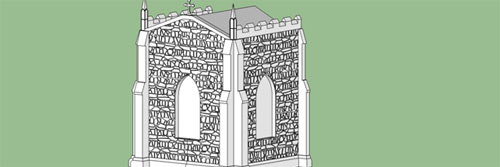

model 3d whit Sketchup 8. by Paolo Daniele. student of 3rd year of Production Design. Academy of Fine Arts of Catanzaro, Italy.

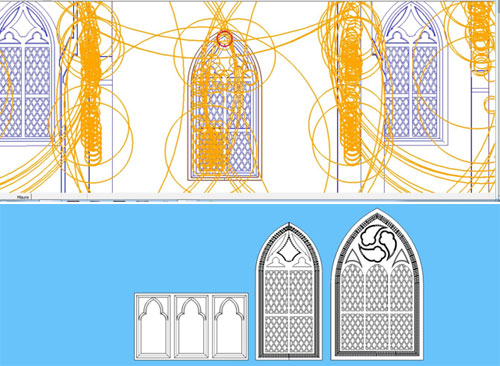

we started a few years ago, the courses in 3d with the use of sketchup. so in addition to modeling, rendering and animation, we became interested in 3D printing, producing a plugin stl files, compatible with a 3D printer trade. This process for the preparation of files, we realized that: the way we design our models in sketchup had to follow the strict rules imposed by 3d printing. do not let double lines, no double intersected faces that are not continuous and connected between them. and a great cleaning of the models, very often all this attention is not enough, how do we know where we have made a mistake? Fortunately for us, helps us a very interesting plugin, which saves us a lot of time to research the error. but the most important thing is to acquire a new design method with sketchup, with models that do not have to submit internal faces hidden, or lines in excess beyond that necessary, and all models must have filled the voids and coincident, in the end you have to consider that the molded object must be closed, like a box, that is, must have a minimum thickness, that the printer interprets as a part to be printed to give a real thickness.

To get our solid printable, consider a design method different from the traditional modeling, through these simple steps:

- Make sure that the 3D model that has no point or line unrelated to his geometry.

- Combine and intersect any faces or lines for the purpose of cleaning the model.

- The correct model for any errors will be recognized as solid from SketchUp plugin and software slicing needed for 3D printing.

- Check that the model is internally empty, uniform and closed, their faces clear turned outward.

- Install within Sketchup plugins needed for export .stl format recognizable by other printing software.

Here are some examples for the creation of a solid:

A plugin that helps a lot to detect problems inside and outside of the solid is "Solid Inspector." by ThomThom

You can download the plugin at this link. http://extensions.sketchup.com/it/content/solid-inspector

in case of errors you will notice a red circle on the element to be corrected.

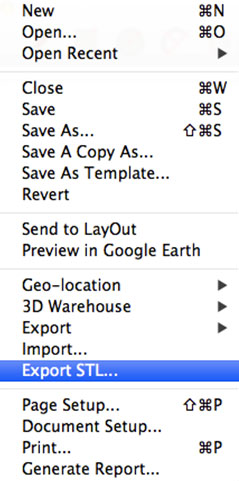

After checking that all the faces are closed and there are no errors proceed exporting the model in STL format

(SketchUp STL)

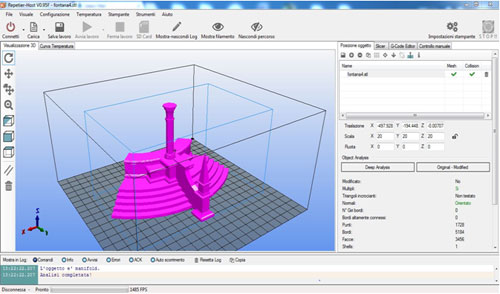

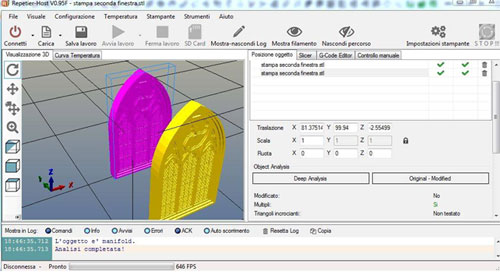

If you have been working properly, the model will be suitable to be printed in any program slicing and 3D printing, then opening it in other programs there will be no negative checkmarks or errors.

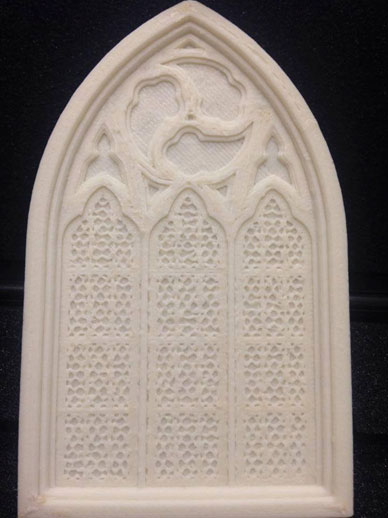

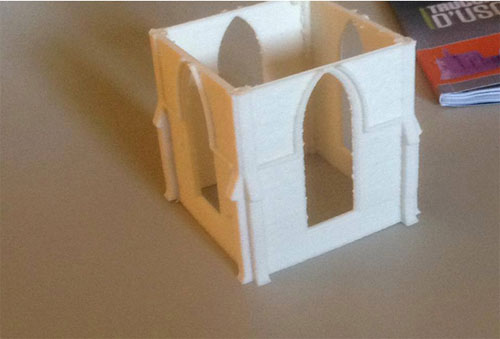

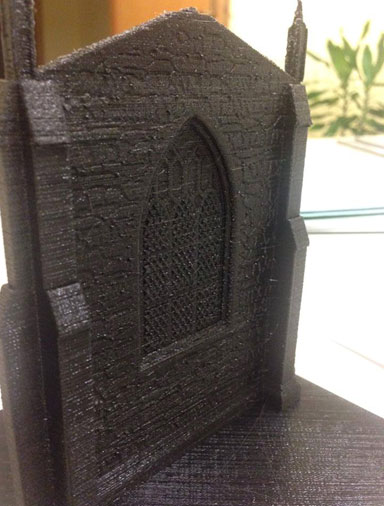

The end result is considerable comparing it with the digital model

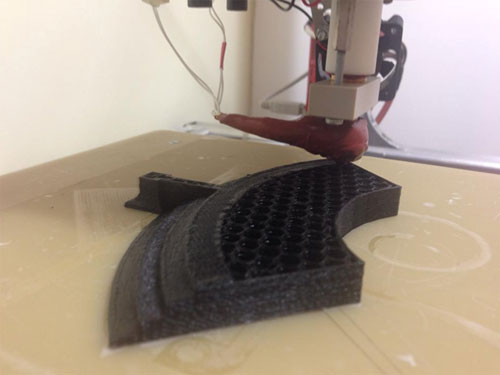

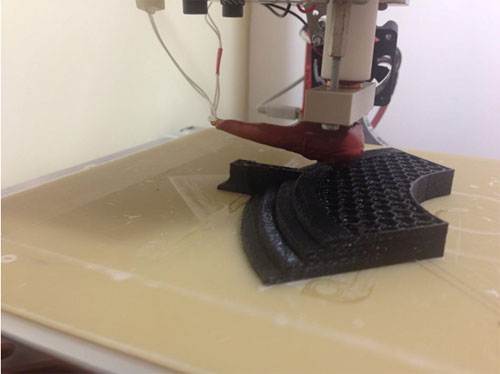

3d printing made by the student Vitaliano Gallo 3nd year of the school of scenography Academy of Fine Arts of Catanzaro.

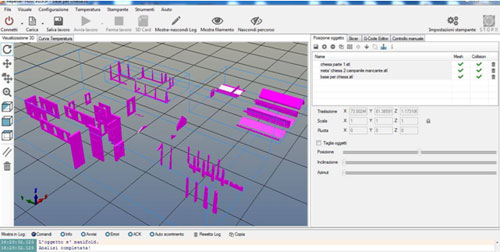

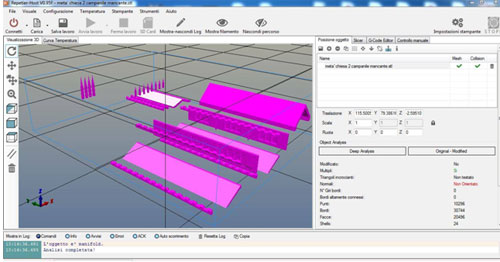

for printing the models must consider that the plate of our 3d printer may contain a model of 20 centimeters x 20 centimeters. then in the planning stage with sketchup must make the pieces that do not exceed these measures, then you can pasting or predispose before with the slots suitable for assembly.

for printing of the models must consider that the plate of our 3d printer may contain a model of 20 centimeters x 20 centimeters. then in the planning stage with sketchup must make the pieces that do not exceed these measures, then you can pasting or predispose before with the slots suitable for assembly.

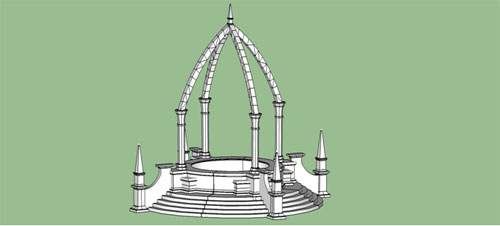

model 3d whit Sketchup 8. by Paolo Daniele. student of 3rd year of Production Design. Academy of Fine Arts of Catanzaro, Italy.

example print medium resolution 3d printing times are acceptable

all these pieces will be printed individually and then hand assembled.

example Print Low Resolution 3d printing times are much faster.

if you do not need many details on your model you can use a print with a detail very low, with a significant printing speed, useful for example for testing.

~~~~~~~~~~~~~~~~~~~~~

Published By

Rajib Dey

~~~~~~~~~~~~~~~~~~~~~

No comments:

Post a Comment