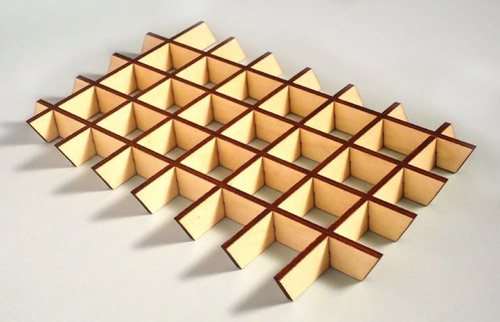

With the

use Google sketchup and the slicemodeler plugin its possible to create laser

cut 3D shapes that snap together without glue.

What you

need:

·

Google stetchup

Step 1:

Install sketchup and plugins

Download

and install sketchup, then download the svg export plugin and the slice

modeller plugin.

Start

sketchup. I use the "Product Design and Woodworking - Millimetres

template"

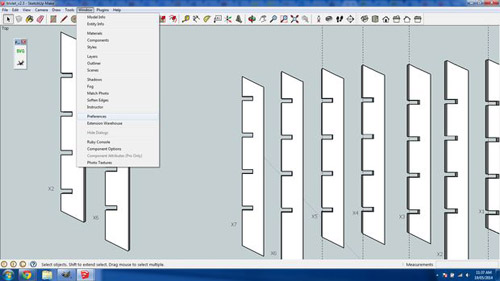

Install

the slice modeler and svg export plugins in google sketchup: Window >

Preferences > Install Extension. Navigate and select the rbz plugin files.

Step 2:

Experiment with different size nodes

The

glue-less design is achieved by placing small curved bumps (nodes) in each

slot. The curve of the bumps allow the parts to slide together but provide

enough pressure on the material to fit together snugly. There are multiple

factors that will influence the size and number of the nodes, including slot

length wood thickness and wood density.

I

highly recommend creating parts with different size and numbers of nodes so you

can find the best fit that works for you. You might want a very hard fit that

needs to be tapped together with a rubber mallet or you might want a fit that

can be assembled by hand without any tools. The only way to find the fit that

works for you is try different size nodes. See this article for more about

nodes.

What

worked for me:

My

trivets are made out of 4mm Italian poplar Plywood and I found that a single

node 5mm wide and having a 0.16mm bulge made a good fit, that could be snapped

together by hand. However different materials will need different node sizes

and you need to figure out what works for you.

Next

we'll create a test object in sketchup to test how various size nodes work with

your chosen material.

Step 3:

Create a test object in sketchup

My test

object is 2cm high and 7cm wide and 7cm long. Using a square test object shape

means all the slices will be the exactly the same. A test object of these

dimensions should be enough to gauge how well the different size nodes work.

The height is the most important factor to get right. So make sure you create a

test object with the same height as your end goal design.

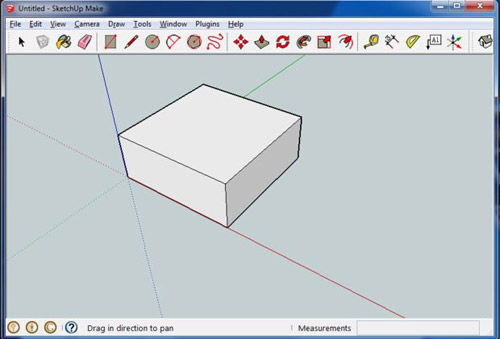

Open

sketchup and create a square 7cm by 7cm and extrude it 2cm up.

Now its

time to slice it up. Select the object and convert it to component by selecting

all (ctrl-A) right clicking on the object and select "make

component". Leave the component name as the default one.

IMPORTANT

sliceModeler changes the model it's slicing so make sure to make a copy of it.

To do this select the model and copy and paste a copy (ctrl-c ctrl-v).

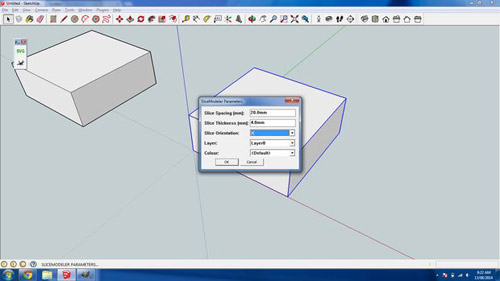

To

slice the model select the component and open the sliceModeler dialogue

(plugins -> sliceModeler). In the sliceModeler dialogue set:

·

slice spacing of 20mm

· slice thickness to the thickness of your material, in my case the

Italian poplar is 4mm thick.

·

slice orientation to X

·

Leave other settings as the default.

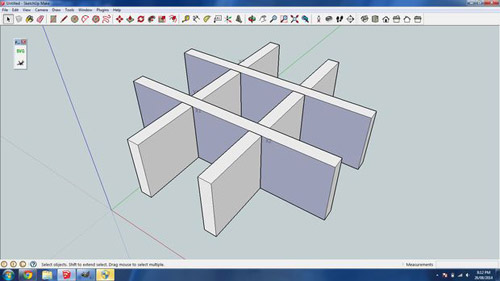

Click

ok and say yes to "adding a number to each slice" and yes to leave

the original hidden. For the Y orientation dialogue leave everything as default

and click yes to "leaving the original section hidden". Click yes to

"make flatten copies", leave minimum gap as default. You now have

flattened slices and an "assembled" model to work with. Next step

we'll add the nodes to a slice.

Step 4:

Adding the nodes to a slice

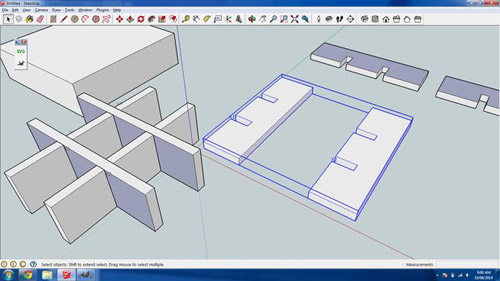

It time

to add the nodes to a slice. I find it easiest to work in a new sketchup file.

Since this model is square all slices are the same so you only need to copy 1

slice. SliceModeler exports the 4 slices as 2 groups. To copy a single slice

double click on the group to edit the group and click on a single slice. Double

check the whole slice is selected and copy it (ctrl-c). Open a new sketchup

window (ctrl-n) and paste your slice in (ctrl-v).

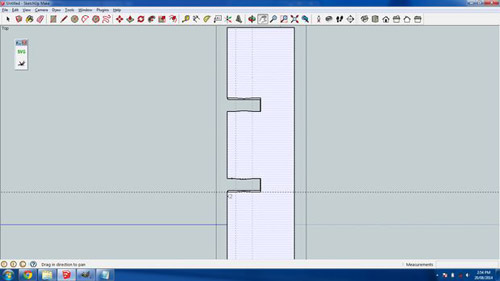

Zoom

into your slice and select the top down view. Your slice should be positioned

as per the image above.

The

node we will create will be 5mm long and have a bulge height of 0.16mm. Click

on the tape measure tool and drag a guide from the left edge of the slice and

set it's distance to 2.5mm. Now create another guide and set it's distance to

7.5mm. Using these guides will ensure the node length is 5mm. Next we'll create

the node bulge.

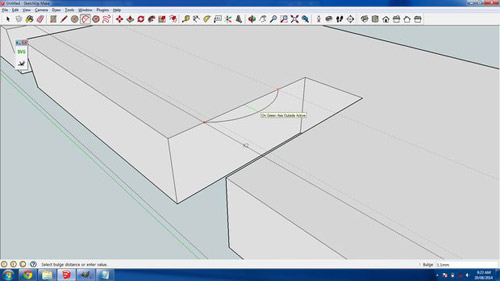

Zoom

right into one of the interlocking slots in the slice and use the orbit tool to

view the gap at an isometric angle as pictured above. Select the arc tool and

create an arc between the two guides as pictured. Make sure the arc is

orientated along the green axis. The line in the arc will change green to

indicate you are on the right axes. Set the bulge height to 0.16mm. IMPORTANT

to create a continuous outline vector for the laser cutter you need to delete

the line behind the arc as pictured. Now repeat the arc for the other side of

the slot and the same again for the 2nd slot.

You

will now have a slice surface with 2 slots and 4 nodes that can be exported to

an svg.

Step 5:

Exporting the slot into inkscape

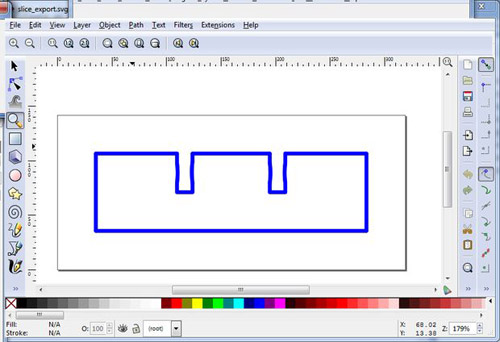

To

export the slice svg out of sketchup select the top down view and select none

(ctrl-T) then select the surface you just created the nodes on (it will be the

top surface). The selected surface will be covered with small dots. Now export

the svg by clicking on the flight of idea SVG icon. Deselect "export

annotations for faces" leave everything else as default, enter a filename

and click ok. Open the file in inkscape and you will see the outline of the

slice as per the screen shot.

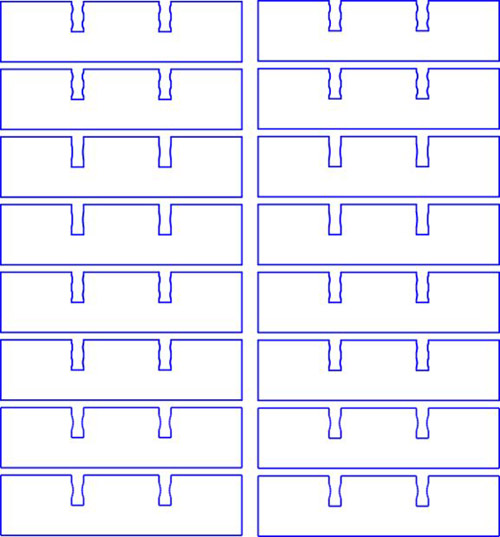

Step 6:

Adding the svg to a laser cutting template

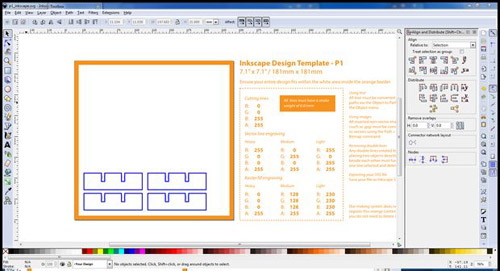

I use

ponoko's laser cutting service to cut my test slices. If you use a different

laser cutting service follow their instructions. For the rest of this step I'll

be talking about ponoko's inkscape template. Download ponoko's inkscape

template from here. I used the p1 18x18cm size template. Open the exported

slice svg in inkscape, select all (ctrl-A) and copy (ctrl-C). Open the ponoko

inkscape template and paste the slice (ctrl-v). Because the test object is

square you can simply paste in three more slices so you have a total of 4.

Arrange the four slices into a rough 2x2 grid. You want the slices all nicely

spaced and aligned so its less movement for the laser. Open inkscape's align

and distribute dialogue (shift-ctrl-A) select the left 2 slices and click

center on vertical axis do the same for the right 2 slices. Do a similar thing

but horizontally. The end result is 4 nicely aligned slices as per the

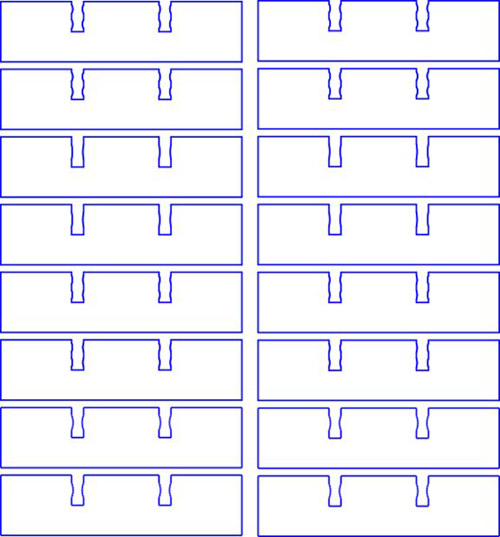

screenshot.

Ponoko

is very specific about the template's cutting line color and stroke width. For

cutting lines the line color must be solid blue and have a stroke weight of

0.1mm. To set the correct color and stroke weight, open the fill and stroke

dialogue, select all (ctrl-A) and double check the stroke paint is R:0 G:0 B:255

A:255 and in the stroke style tab set the width to 0.01mm. The cutting lines in

the template should be barley visible. Before uploading the template to ponoko

do a sanity check of the cutting vectors. The easiest way to do this is select

outline display mode (view -> display mode -> outline) and zoom right

into each vector and make sure there are no gaps that will result in an unclean

cut.

Your

done! Your now ready to upload the template to ponoko for cutting! However I

see much more space in the template for slices with different node sizes. In

the next step I'll discuss experimenting with different node sizes.

Step 7:

Expermenting with different node sizes

The

ponoko template has enough room for 16 slices, so in a single cutting order you

can create 4 test objects each with different node sizes. In the pictured file

I create 4 test objects with the following node configurations:

·

single node with bulge height of 0.4mm

·

single node with bulge height of 0.2mm

·

double nodes with bulge height of 0.4mm*

·

double nodes with bulge height of 0.2mm*

(A

double node is where you have 2 smaller nodes in a slot, this gives better

stability then a single node but its harder to assemble).

With

the 4mm Italian poplar I found the 0.4mm single node too hard to assemble by

hand. I also found the two double node test objects too hard to assemble.

I did

find the 0.2mm possible to assemble by hand but it was a touch harder then I'd

like, so I dropped the node bulge to 0.16mm. And when I received my next ponoko

order the 0.16mm bulge height was quite easy to assemble by hand. It also

provided firm interlocking parts that "click" together. Now back to

your test object(s).

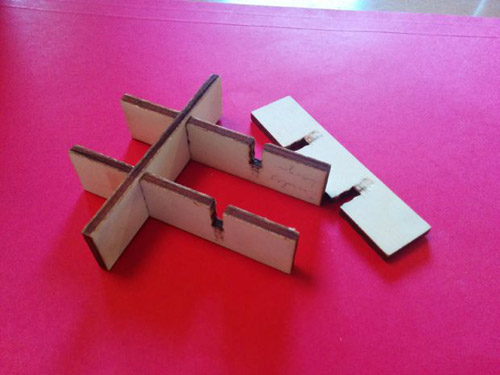

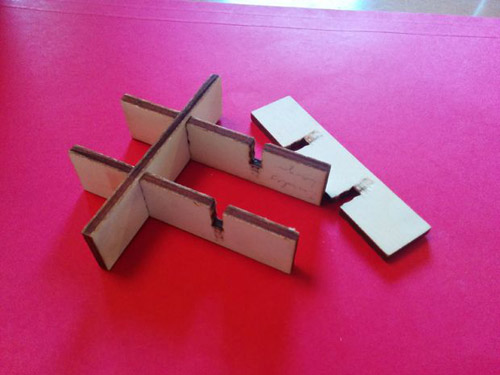

Step 8:

Assembling the test objects

Once

you have received your order from ponoko your now ready to assemble the test

objects. But first write on each slice which node configuration it is, as its

easy to forget. Now attempt to assemble each test object while taking notes on

how hard or easy it is to assemble. If you find the right balance between ease

of assembly and "fit" then your done. Otherwise if none work, take

note if the fit is too loose or tight and repeat the process.

Congratulations! You can

now make awesome interlocking laser cut products that can be hand assembled and

don't require any glue!

~~~~~~~~~~~~~~~~~~~~~

Published By

Rajib Dey

~~~~~~~~~~~~~~~~~~~~~

No comments:

Post a Comment